This article describes Variantum’s point of view for different processes to manage customer-driven products from design to sales and to manufacturing based on product volumes and design- and sales strategies.

Many manufacturing companies have found benefits of shifting to order-driven production (MTO = Make-to-Order) instead of the inventory-driven output (Make-to-Stock), because it has allowed lower value of inventories. Sometimes to fulfill customer or market needs make-to-stock is needed, for example during campaign, and the combination of both might support the product strategy fully. In general, companies that do not have standard products tend to operate in an entirely order-driven manner.

For the Make-to-Order process to be effective, customer needs should already be broadly covered by what the company offers. This is called mass customization, and it allows highly automated product offer-order functions. In mass customization, the features which are the customer needs are pre-designed, and the company designs and manages product families.

For the Make-to-Order process to be effective, customer needs should already be broadly covered by what the company offers. This is called mass customization, and it allows highly automated product offer-order functions. In mass customization, the features which are the customer needs are pre-designed, and the company designs and manages product families.

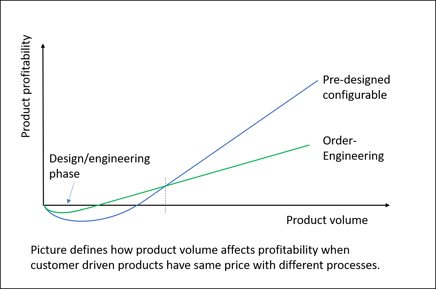

The higher the volume the more useful automation is for the company as a faster operation in the quotation, ordering and manufacturing phase. Mass customized products are designed with design tools and accompanied by selections, product rules and, for dimensionally variable products, possibly also CAD robotics. Creating a product family and its rules requires resources, but with a production volume of dozens of individuals per year, it is already profitable.

The companies have described order-driven production for the needs of different products. If the product’s volume is small, it may be left entirely for design as an Engineer or Design-to-Order process. Higher volume products, on the other hand, are manufactured using the configure-to-order process. In different companies, these processes can be divided into different products or product types, e.g. A, B, C and D processes. For example, the A process is a fully configurable product from quotation to order and manufacturing. In contrast, the D process is customizable according to the customer's needs and requires order-specific design and corresponds to the Design-to-Order process.

The Make-to-Order process can be roughly divided into three different approaches:

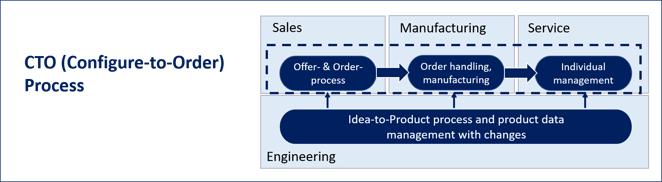

- CTO, or Configure-to-Order, means that the product is pre-designed, and sales only sell pre-designed configurable product variants to meet customer needs. CTO is what many companies strive for, as it allows the overall offer-order-delivery process to be optimized and automated. However, this might pose challenges for product development. The product development process (Idea-to-Product) must be organized well. Ideas for product development need to be actively collected from different sources, for example from customers and competitors. Additionally, new available technologies or components have to be taken into account as well. Product development adds product rules that can be utilized in sales and production configuration. Product changes and updates from sales to maintenance are updated automatically. The bottleneck in this process is typically sourcing and/or manufacturing capacity.

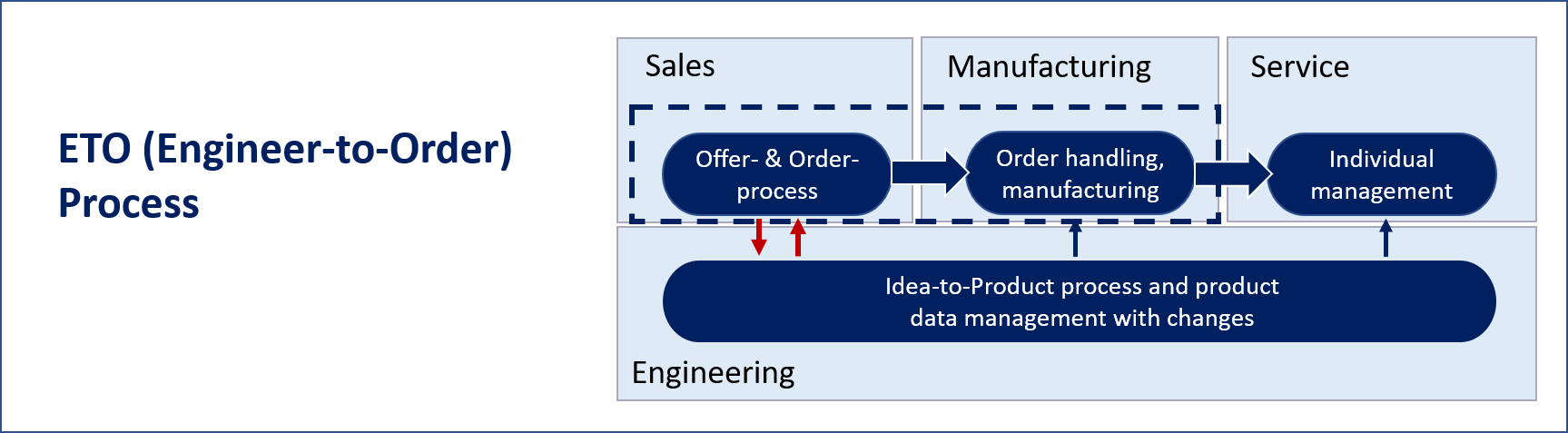

- ETO, or Engineer-to-Order, means that the product is pre-designed as in the CTO process, but small changes are allowed. Small changes mean changes that can be made by the sales or sales support. In this case, the aim is to offer the product flexibly so that price and product changes are possible, and the customer's special needs can be taken into account without changing the basic product. It may be challenging to update the changes to production.

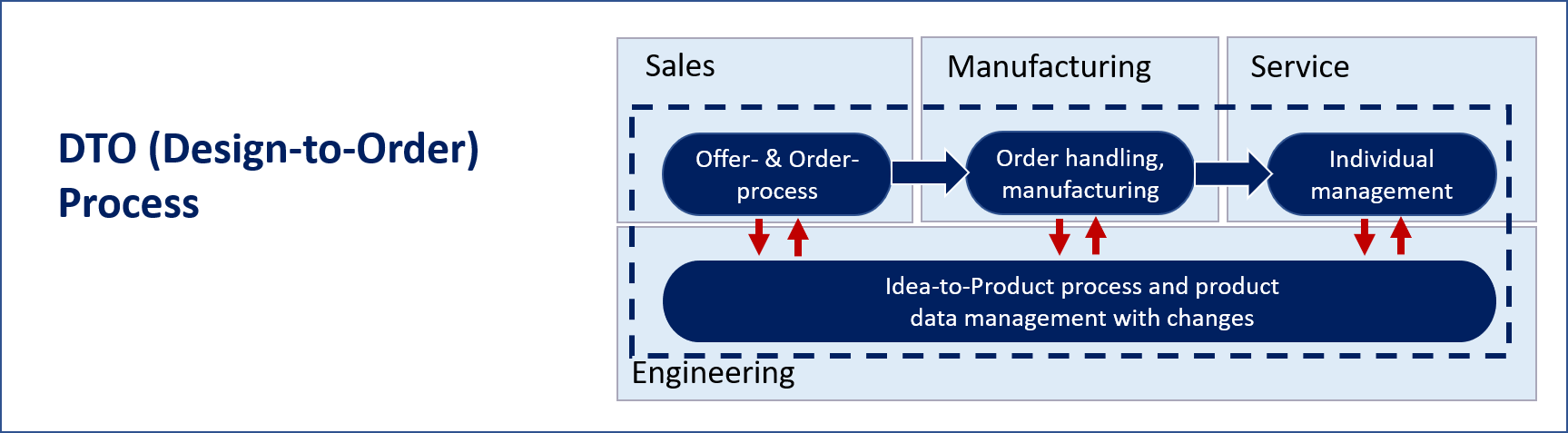

- DTO, or Design-to-Order, means that a product or part of a product is configured close to the customer's need, but redesign or additional design is needed to meet the customer's need. In this case, the co-operation of sales and product design is required already at the tender stage. The result of the configuration has to be usable so that it is easy to make customer changes to the product with the design tools. These changes can then be saved and utilized into manufacturing. Sometimes the need for a change is so extensive that the product model cannot be utilized, but the product has to be developed almost completely or the order is processed as a project delivery. In DTO, design capacity can be a bottleneck, also updating to production with changed data and ensuring the quality of design can be challenging.

After delivery, the technical information of the products should be managed for service and after-sales needs, especially if the company has maintenance or spare parts business. As the product changes and evolves over time, it is a good idea to see revision or component changes to the base product as well as customer-specific changes. Sometimes spare parts or product modules contain customer-specific ordering parameters and require configuration in order to be offered or delivered to a customer-specific product. In this case, we are talking about reconfiguring or configuring the spare part.

Variantum supports especially MTO customers because product information management (PDM / PLM), sales configuration (CPQ - Configure-Price-Quote), product configuration for production and product individual management are our key areas of expertise, and we have a flexible software solution for them. Variantum's solutions are used by many well-known Finnish companies. Variantum helps in different areas of the MTO process as well as in consulting.

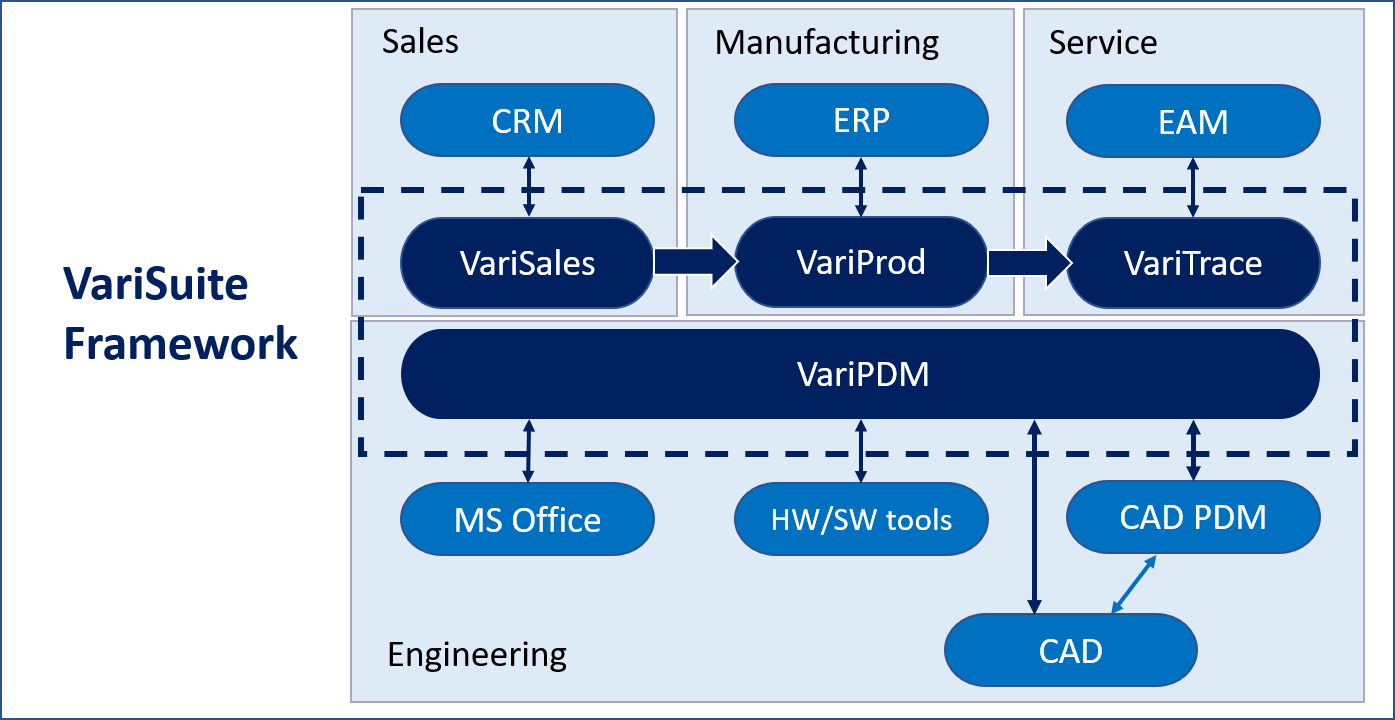

VariSuite manages the offering and MTO processes of different product types in the single database, integrating with the company's existing systems, such as CRM, ERP, maintenance systems (EAM = Enterprise Asset Management) and design tools. Our solution manages the same product information jointly between different systems and organizations: this makes optimizing and automating quotation-order-delivery-maintenance process possible. At VariSuite, product and price modeling is done quickly as modifying product data can be done by your own organization, making rapid changes possible and cost-effective.